Common Technology of Printing and Packaging Materials (part 5)

Summary:Printing is a technology that transfers ink to the surface of paper, fabric, plastic, leather and other materials and copies the contents of the original in batches through the process of plate making, ink application, pressure and so on. Printing is the process of transferring the approved printing plate to the substrate through printing machinery and special ink.

Common Technology of Printing and Packaging Materials (part 5)

Common processes of other materials

Printing is a technology that transfers ink to the surface of paper, fabric, plastic, leather and other materials and copies the contents of the original in batches through the process of plate making, ink application, pressure and so on. Printing is the process of transferring the approved printing plate to the substrate through printing machinery and special ink.Common processes of other materials

20. Paint

a. On the base ground to a certain roughness, spray several layers of paint, and bake at high temperature.

b. There are many kinds of colors, please refer to Pan‘’tone. But it can only be solid color, not gradient color.

21. Oxidation treatment

a. For the surface treatment process of aluminum or aluminum alloy, oxidation treatment produces surface oxide film on the surface.

b. Color optional, refer to Pan'tone. Compared with the baking varnish, the metal texture is increased, but only the solid color can not present the gradient color.

22. Carbon fiber treatment

a. It is a new type of fiber material with high strength and high modulus, which contains more than 95% carbon content. It has the advantages of conduction, heat conduction, corrosion resistance, high temperature resistance, wear resistance, light weight, radiation protection and other materials.

b. After treatment, the texture of carbon fiber is presented, and the color is optional.

23. Electroplating treatment

a. The process of plating a thin layer of other metals or alloys on the surface of some metals by the principle of electrolysis.

b. Commonly used gold, silver and chromium plating.

24. Screen printing

a. By pressing the scraper, the ink is transferred to the substrate through the mesh of the image and text part to form the same image and text as the original.

b. There are many colors for silk screen printing. Please refer to Pan'tone color card, but gradient printing cannot be realized.

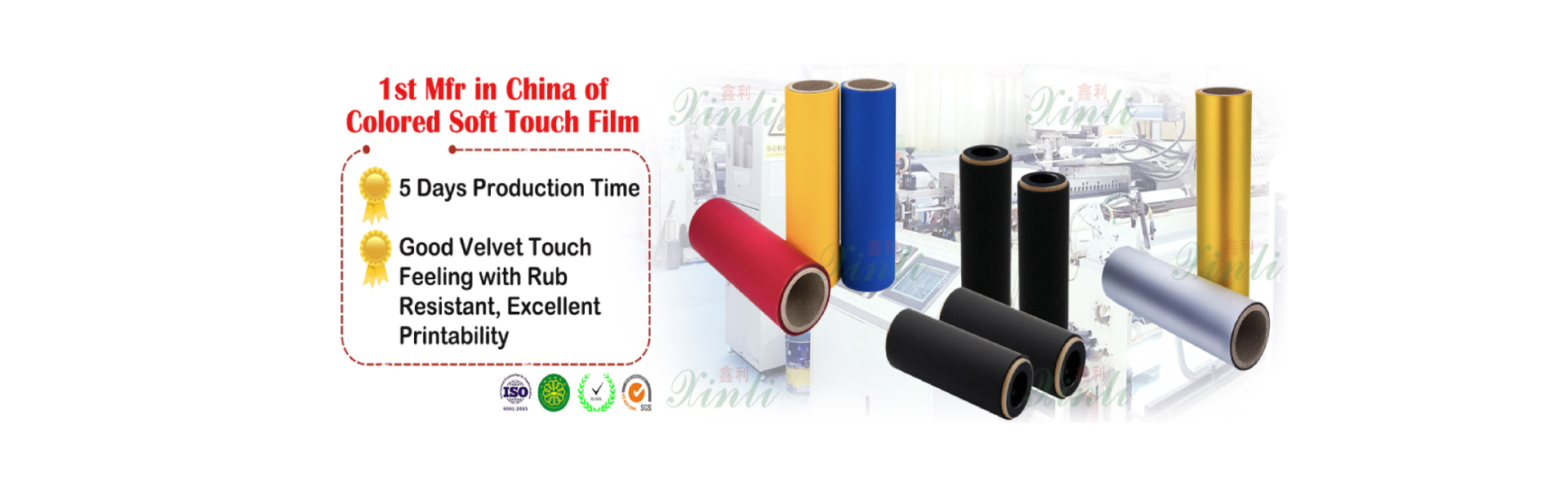

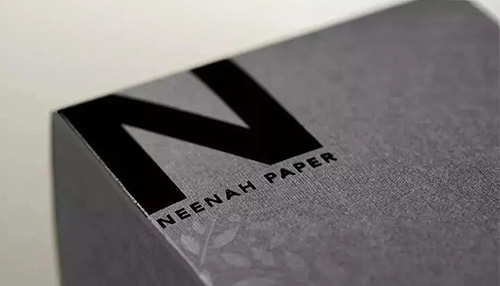

Remark: For this type of box, BOPP thermal lamination matte film could be use on the outter face. It also offers excellent effects in applications of spot UV, hot stamping and screen printing. With special treatment based on Matte film, BOPP Soft touch film and BOPP Anti scratch film are popularly used for book covers, magazines, brochures, deluxe gift boxes, mobilephone boxes etc.

25. Pad printing

a. Pad printing refers to the way in which the substrate is irregular and irregular, copper or steel intaglio plate is used to form a hemispherical pad head through silicon rubber, and then the ink is transferred to the substrate to complete the transfer printing. In short, pad printing can print small and multicolor overprint products, there is no requirement for product shape.

b. Pad printing can achieve a lot of effects that screen printing can not achieve.

(to be continue...)

Go to: Common Technology of Printing and Packaging Materials (part 4)

Go to: Common Technology of Printing and Packaging Materials (part 3)

Go to: Common Technology of Printing and Packaging Materials (part 2)

Go to: Common Technology of Printing and Packaging Materials (part 1)

Tag for more popular products:

BOPP thermal lamination matte film

BOPP Soft touch film

BOPP Anti scratch film

BOX printing and packaging use

Gift box laminating and packing

PET metalized film gold and silver,

Holographic film;

For more info, please read our website: https://www.post-printing.com/

Products Search