Common Technology of Printing and Packaging Mater

Summary:Printing is a technology that transfers ink to the surface of paper, fabric, plastic, leather and other materials and copies the contents of the original in batches through the process of plate making, ink application, pressure and so on. Printing is the process of transferring the approved printing plate to the substrate through printing machinery and special ink.

Common Technology of Printing and Packaging Materials

Printing is a technology that transfers ink to the surface of paper, fabric, plastic, leather and other materials and copies the contents of the original in batches through the process of plate making, ink application, pressure and so on. Printing is the process of transferring the approved printing plate to the substrate through printing machinery and special ink.

1. Four colors printing

a. The so-called four colors are: cyan (c), magenta (m), yellow (y), black (k). All colors can be mixed by these four inks, and finally achieve color graphics and text.

b. The most common and common printing, with different effects printed on different substrate.

2. Spot color printing

a. Spot color printing refers to printing the color with a special ink, which is brighter than the color mixed with four colors. Commonly used are special gold and special silver.

b. There are many spot colors. Referring to Pan'tone color card, spot color can't achieve gradient printing. If necessary, four-color printing will be added.

3. Laminating, BOPP Thermal Glossy film

a. After printing, the transparent BOPP lamination film is laminated to the surface of the printed product by hot pressing to protect and increase the luster. Glossy film makes the surface bright, as shown in the figure below.

b. The most basic process of paper surface treatment. Similarly, there is the varnish, but the BOPP film can enhance the hardness and tensile properties of the paper.

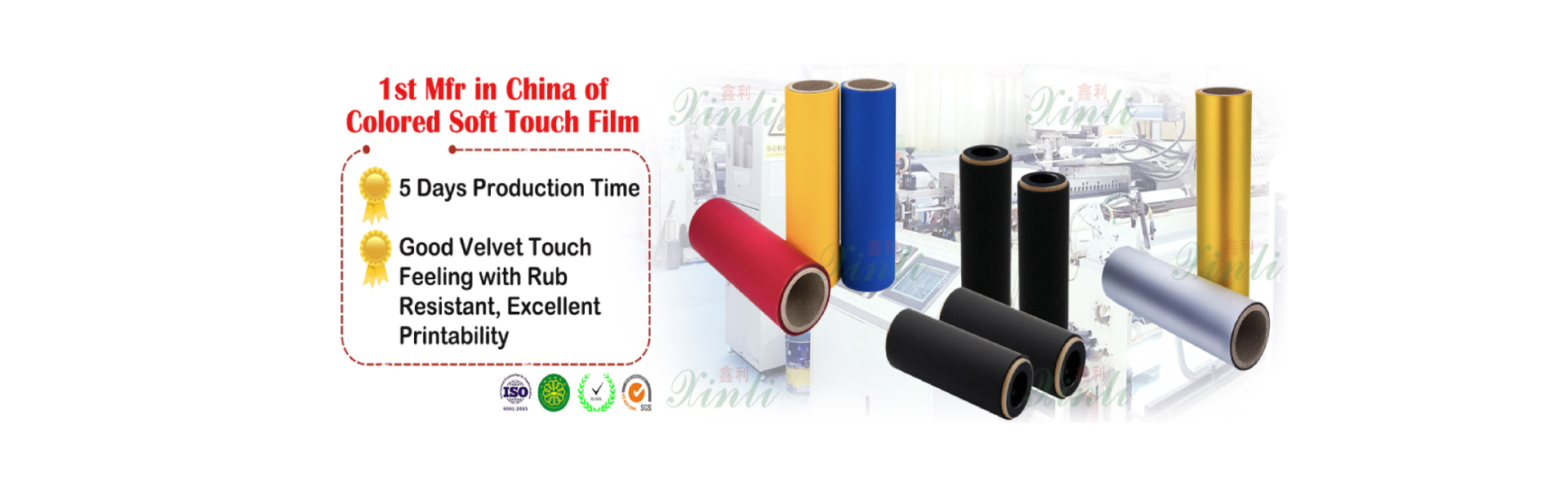

3. Different types of lamination film: glossy, matte, Soft touch film, Anti scratch film, PET metalized film gold and silver, Holographic film and so on.

4. Laminating, BOPP Thermal Matte film

a. After printing, the transparent BOPP lamination film is laminated to the surface of the printed product by hot pressing to protect and increase the luster. Matte film makes the surface matte finish, as shown in the figure below.

b. The most basic process of paper surface treatment. Similarly, there is the varnish, but the BOPP film can enhance the hardness and tensile properties of the paper.

3. Different types of lamination film: glossy, matte, Soft touch film, Anti scratch film, PET metalized film gold and silver, Holographic film and so on.

tag: BOPP Thermal Glossy film, BOPP Thermal Matte film, Soft touch film, Anti scratch film, PET metalized film gold and silver, Holographic film;

Products Search